Audi A6 Typ 4G: Bearing Bushing and Guide Pin, Replacing

Bearing Bushing and Guide Pin, Replacing, Steel Brakes 1LA/1LJ

Special tools and workshop equipment required

- Lithium grease. Refer to the Parts Catalog.

Removing

- Remove the brake pads. Refer to → Chapter "Brake Pads, Removing and Installing, Steel Brakes, 1LA/1LJ".

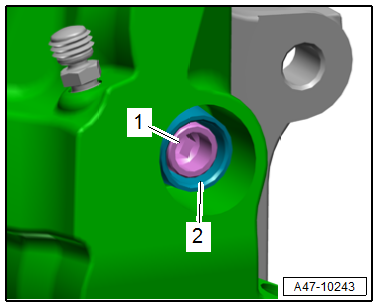

- Remove the bearing bushing -2- on the outside from the groove on the guide pin -1-.

- Pull the guide pin outward from the bearing bushing.

- Pull the bearing bushing out of the brake caliper.

Installing

- Thinly coat the guide pin with grease from the repair kit.

- Carefully press the guide pin into the bearing bushing as far as the first groove.

- Insert the bearing bushing into the brake caliper.

- The bearing bushing must be seated in the center of the brake caliper.

- Push the guide pin through the bearing bushing.

- The bearing bushing must not be seated in both grooves on the guide pin.

- Check the movement of both guide pins.

- Both guide pins must be able to slide.

- Install the brake pads. Refer to → Chapter "Brake Pads, Removing and Installing, Steel Brakes, 1LA/1LJ".

Bearing Bushing and Guide Pin, Replacing, Steel Brakes 1LF/1LL

Special tools and workshop equipment required

- Lithium grease. Refer to the Parts Catalog.

Removing

- Remove the brake pads. Refer to → Chapter "Brake Pads, Removing and Installing, Steel Brakes, 1LF/1LL".

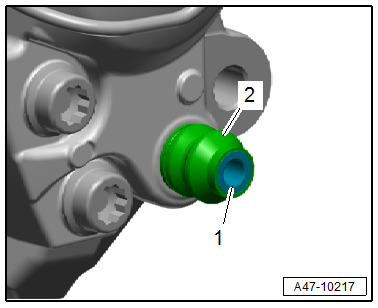

- Pull the guide pin -1- outward from the bearing bushing.

- Pull the bearing bushing -2- out of the brake caliper.

- Insert the bearing bushing into the brake caliper.

- The bearing bushing must be seated in the center of the brake caliper.

- Thinly coat the guide pin with grease from the repair kit.

- Push the guide pin into the bearing bushing.

- Check the movement of both guide pins.

- Both guide pins must be able to slide.

- Install the brake pads. Refer to → Chapter "Brake Pads, Removing and Installing, Steel Brakes, 1LF/1LL".