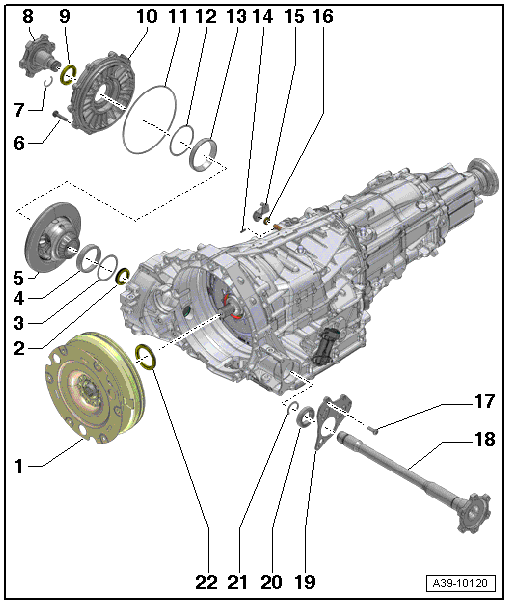

Audi A6 Typ 4G: Final Drive

Overview - Final Drive

1 - Flywheel

- Removing and installing. Refer to → Chapter "Flywheel, Removing and Installing".

2 - Shaft Seal

- For the left flange shaft

- Between the final drive and the transmission housing

- Replacing. Refer to → Chapter "Left Seal, Replacing".

3 - Shim

- Behind the taper roller bearing outer race

4 - Taper Roller Bearing Outer Race

5 - Differential

6 - Bolt

- Quantity 10

- Tightening specification and sequence. Refer to → Fig. "Tightening Specification and Sequence, Front Final Drive Cover"

7 - Locking Ring

- Replacing

8 - Right Flange Shaft

- Removing and installing. Refer to → Chapter "Right Flange Shaft, Removing and Installing".

9 - Shaft Seal

- For the right flange shaft

- Replacing. Refer to → Chapter "Right Seal, Replacing".

10 - Front Final Drive Cover

- Removing and installing. Refer to → Chapter "Left Seal, Replacing".

11 - O-Ring

- On the front final drive cover

- Replacing

12 - Shim

- Behind the taper roller bearing outer race

13 - Taper Roller Bearing Outer Race

14 - Spring Pin

15 - Gearshift Lever

16 - Shaft Seal

- For the selector shaft

- Replacing. Refer to → S tronic Transmission; Rep. Gr.34; Selector Mechanism; Selector Shaft Seal, Replacing

17 - Bolt

- 10 Nm + 45º

- Quantity: 3

18 - Left Flange Shaft

- Removing and installing. Refer to → Chapter "Left Flange Shaft, Removing and Installing".

19 - Bracket

- Attached to the left flange shaft with the ball bearing -20- and the circlip -21-

- Check for traces of wear on the bearing bracket and check the pre-tension on the ball bearing for the left flange shaft. Refer to → Chapter "Left Flange Shaft Ball Bearing Pre-Tension, Checking and Adjusting"

20 - Ball Bearing

- For the left flange shaft

- Left Flange Shaft Ball Bearing Pre-Tension, Checking. Refer to → Chapter "Left Flange Shaft Ball Bearing Pre-Tension, Checking and Adjusting"

- Replacing. Refer to → Chapter "Left Flange Shaft Ball Bearing Mounting Bracket, Removing and Installing".

21 - Locking Ring

- For the left flange shaft bearing

- Replacing

22 - Shaft Seal

- For the input shaft

- Replacing. Refer to → Chapter "Input Shaft Seal, Replacing".

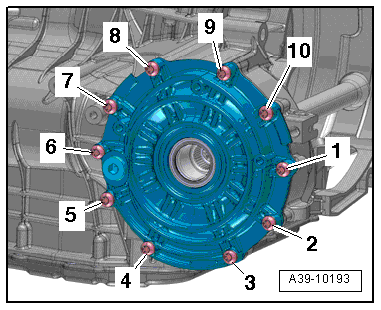

Tightening Specification and Sequence, Front Final Drive Cover

Note

Note

Replace any bolts that were tightened with an additional turn.

- Tighten the bolts in three steps in the sequence shown:

.png)