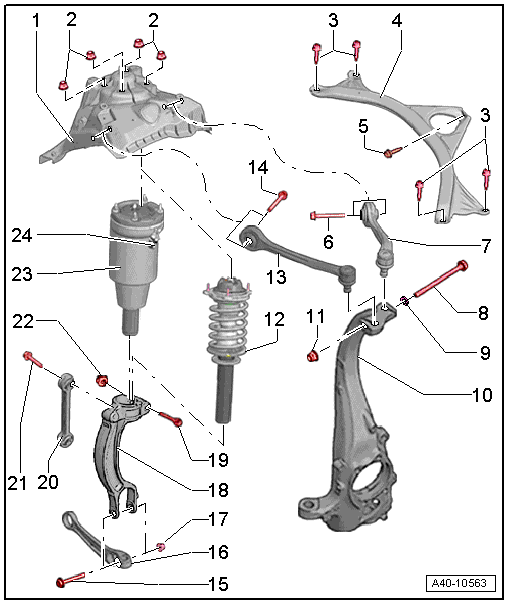

Audi A6 Typ 4G (2011–2018) Workshop Manual / Chassis / Suspension, Wheels, Steering / Front Suspension / Overview - Suspension Strut and Upper Control Arm

Audi A6 Typ 4G: Overview - Suspension Strut and Upper Control Arm

1 - Suspension Strut Dome

2 - Nut

- 30 Nm

- Loosen and tighten diagonally

- Always replace if removed

3 - Bolt

- 20 Nm

4 - Tower Brace

- Removing and installing. Refer to → Chapter "Tower Brace, Removing and Installing".

5 - Bolt

- 20 Nm

6 - Bolt

- 50 Nm +90º turn

- Always replace if removed

- Must be tightened in the control position. Refer to → Chapter "Wheel Bearing in Control Position, Lifting Vehicles with Air Suspension" or → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

7 - Upper Rear Control Arm

- Removing and installing. Refer to → Chapter "Upper Control Arm, Removing and Installing".

- For replacing the bonded rubber bushing for upper rear control arm. Refer to → Chapter "Upper Control Arm Bearing, Replacing".

8 - Bolt

- Always replace if removed

9 - Washer

10 - Wheel Bearing Housing

11 - Nut

- 40 Nm

- Always replace if removed

12 - Coil Spring Shock Absorber

- Removing and installing. Refer to → Chapter "Suspension Strut, Removing and Installing, Coil Spring Shock Absorber".

- Servicing. Refer to → Chapter "Suspension Strut, Servicing, Coil Spring Shock Absorber".

13 - Upper Front Control Arm

- Removing and installing. Refer to → Chapter "Upper Control Arm, Removing and Installing".

- For replacing the bonded rubber bushing for upper front control arm. Refer to → Chapter "Upper Control Arm Bearing, Replacing".

14 - Bolt

- 50 Nm +90º turn

- Always replace if removed

- Must be tightened in the control position. Refer to → Chapter "Wheel Bearing in Control Position, Lifting Vehicles with Air Suspension" or → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

15 - Bolt

- Always replace if removed

16 - Control Arm

17 - Nut

- 90 Nm +90º turn

- Always replace if removed

- Must be tightened in the control position. Refer to → Chapter "Wheel Bearing in Control Position, Lifting Vehicles with Air Suspension"

18 - Shock Absorber Fork

- Removing and installing. Refer to → Chapter "Shock Absorber Fork, Removing and Installing".

19 - Bolt

- 40 Nm +180º turn

- Always replace if removed

20 - Coupling Rod

21 - Bolt

- 40 Nm +90º turn

- Always replace if removed

- Must be tightened in the control position. Refer to → Chapter "Wheel Bearing in Control Position, Lifting Vehicles with Air Suspension" or → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

22 - Nut

- Always replace if removed

23 - Air Spring Shock Absorber

- Removing and installing. Refer to → Chapter "Suspension Strut, Removing and Installing, Air Spring Damper".

- Servicing. Refer to → Chapter "Suspension Strut, Servicing, Air Spring Damper".

- There are different versions of the suspension. Refer to → Chapter "Production Control Number (PR number) Explanation".

24 - Connecting Piece for the Air Line and the Residual Pressure Retaining Valve

- Tightening specification: -Item 5-

- Only remove if vehicle is raised and air spring damper is unloaded (otherwise, there is a risk of injury from lowering vehicle)

- If there are leaks. Refer to → Chapter "Air Line, Servicing" or → Chapter "Air Line, Servicing".

- Clean connections before loosening

- Air escapes when connections are unscrewed

- Protect threaded connection from dirt

- Do not loosen the residual pressure retaining valve.