Audi A6 Typ 4G: Overview - Wheel Bearing

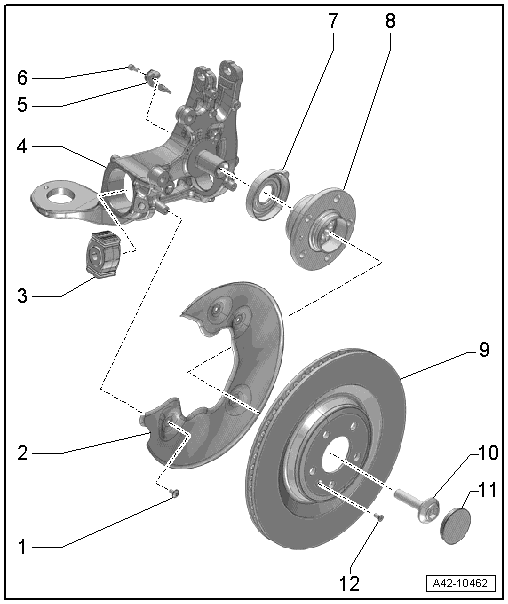

Overview - Wheel Bearing, Vehicles with FWD

1 - Bolt

- 10 Nm

2 - Cover Plate

- For the brake rotor

3 - Bonded Rubber Bushing

- Replacing. Refer to → Chapter "Wheel Bearing Housing Bonded Rubber Bushing, Replacing, AWD Vehicles".

4 - Wheel Bearing Housing

- Removing and installing. Refer to → Chapter "Wheel Bearing Housing, Removing and Installing, FWD Vehicles".

5 - Rear Speed Sensor

- Left Rear ABS Wheel Speed Sensor -G46-

- Right Rear ABS Wheel Speed Sensor -G44-

6 - Bolt

- Tightening specification. Refer to → Brake System; Rep. Gr.45.

7 - Front Seal

8 - Wheel Hub

Caution

Caution

Avoid contaminating with dirt and damaging the seal when setting down/storing. Refer to → Fig. "Avoid Contaminating with Dirt and Damaging the Seal When Setting Down/Storing.".

- Wheel bearing unit, removing and installing. Refer to → Chapter "Wheel Bearing Unit, AWD, Removing and Installing".

- For servicing the wheel bearing unit. Refer to → Chapter "Wheel Bearing Unit, Servicing".

9 - Brake Rotor

10 - Bolt

- 200 Nm +180º turn

- Always replace if removed

- Follow the assembly information when loosening and tightening. Refer to → Chapter "Drive Axle Threaded Connection, Loosening and Tightening".

11 - Dust Cap

12 - Bolt

- Tightening specification. Refer to → Brake System; Rep. Gr.46.

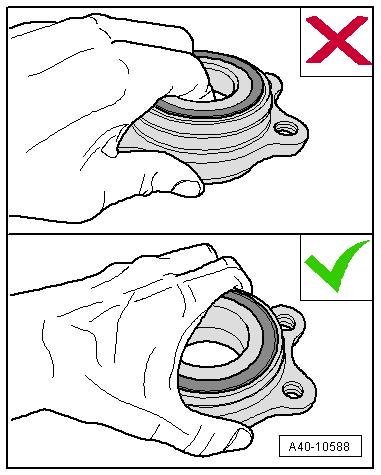

Avoid Contaminating with Dirt and Damaging the Seal When Setting Down/Storing.

- The wheel bearing -1- must always face up.

- Always set the wheel bearing unit down on the wheel hub -2-.

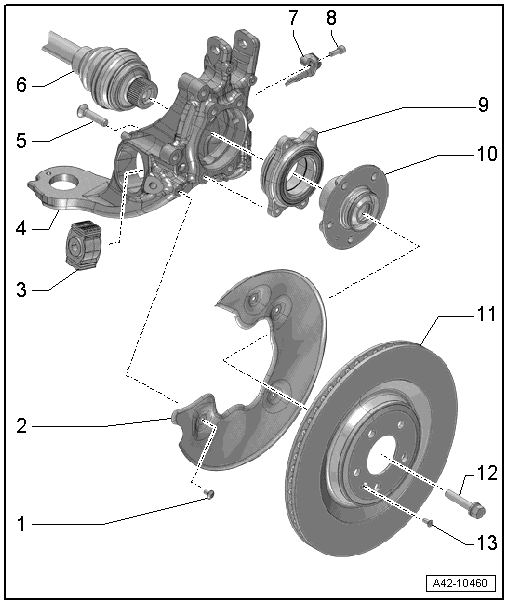

Overview - Wheel Bearing Housing, Vehicles with AWD

1 - Bolt

- 10 Nm

2 - Cover Plate

- For the brake rotor

3 - Bonded Rubber Bushing

- Replacing. Refer to → Chapter "Wheel Bearing Housing Bonded Rubber Bushing, Replacing, AWD Vehicles".

4 - Wheel Bearing Housing

- Removing and installing. Refer to → Chapter "Wheel Bearing Housing, AWD, Removing and Installing".

5 - Bolt

- 80 Nm +90º turn

- Always replace if removed

6 - drive axle

- There are different versions. Refer to the Parts Catalog.

7 - Rear Speed Sensor

- Left Rear ABS Wheel Speed Sensor -G46-

- Right Rear ABS Wheel Speed Sensor -G44-

8 - Bolt

- Tightening specification. Refer to → Brake System; Rep. Gr.45.

9 - Wheel Bearing

Caution

Caution

Avoid contaminating with dirt and damaging the seal when lifting, setting down/storing. Refer to → Fig. "Avoid Contaminating with Dirt and Damaging the Seal When Lifting, Setting Down/Storing.".

- Wheel bearing unit, removing and installing. Refer to → Chapter "Wheel Bearing Unit, AWD, Removing and Installing".

- For servicing the wheel bearing unit. Refer to → Chapter "Wheel Bearing Unit, Servicing".

10 - Wheel Hub

Caution

Caution

Avoid contaminating with dirt and damaging the seal when lifting, setting down/storing. Refer to → Fig. "Avoid Contaminating with Dirt and Damaging the Seal When Lifting, Setting Down/Storing.".

- Wheel bearing unit, removing and installing. Refer to → Chapter "Wheel Bearing Unit, AWD, Removing and Installing".

- For servicing the wheel bearing unit. Refer to → Chapter "Wheel Bearing Unit, Servicing".

11 - Brake Rotor

12 - Bolt

- Tightening specification -Item 14-.

13 - Bolt

- Tightening specification. Refer to → Brake System; Rep. Gr.46.

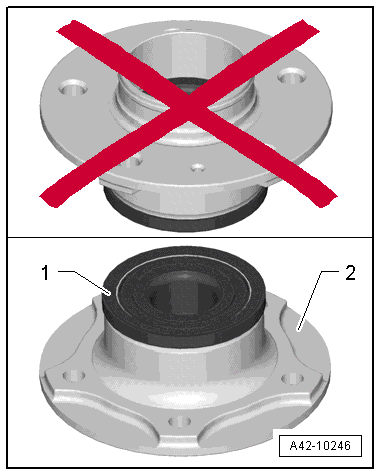

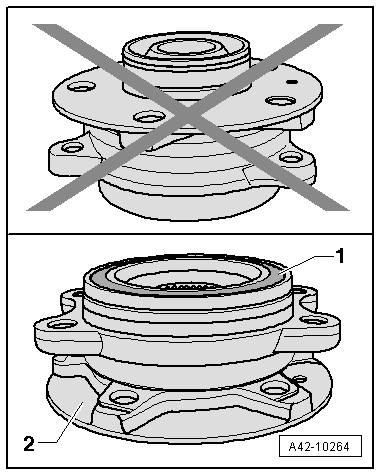

Avoid Contaminating with Dirt and Damaging the Seal When Lifting, Setting Down/Storing.

- The wheel bearing -1- must always face up.

- Always set the wheel bearing down on the wheel hub -2-.

- Never reach into the inside when lifting the wheel bearing.

- Hold the wheel bearing only on the outside.

The same procedure also applies to the wheel bearing without a wheel hub.